-

-

FEATURES:

White crystal powder. Due to its properties it is used in production of explosives for civil use, as well as in pyrotechnics. -

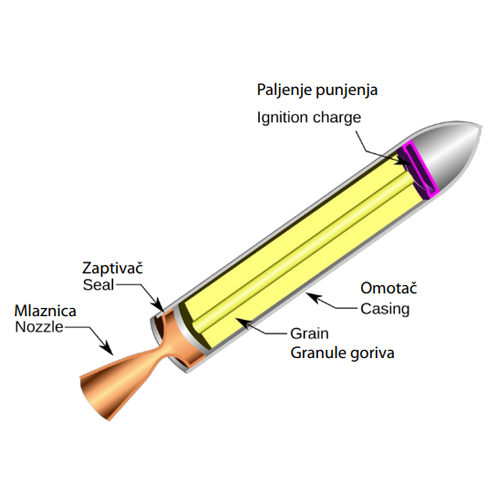

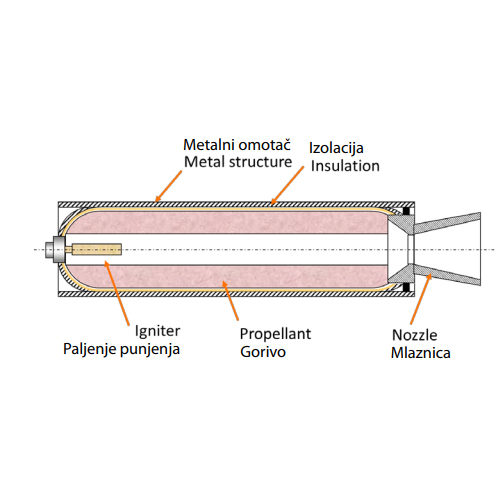

A rocket engine is a type of jet engine that uses only stored rocket propellant mass for forming its high speed propulsive jet. Rocket engines are reaction engines, obtaining thrust in accordance with Newton’s third law. Most rocket engines are internal combustion engines, although non-combusting forms (such as cold gas thrusters) also exist. Vehicles propelled by rocket engines are commonly called rockets. Since they need no external material to form their jet, rocket engines can perform in a vacuum and thus can be used to propel spacecraft and ballistic missiles.

-

POLINEL - nonelectric initiation system used for performing different kinds of miner work (surface and underwater). Not applicable in inflammable conditions or pits with methane. Approved at Safety Institute in Belgrade. POLINEL - PK is composed of initial energy tube, detonator DK-6 with appropriate (0-176) delay placed into plastic case- connector. Into this plastic case (connector) maximum 4 initial low energy POLINEL tubes can be placed. POLINEL - MS (explosive charge initiator) is used for initiation of explosive charge in miner drill holes, composed of low energy tube - NES and belonging detonator DK - 8 with 500 ms delay. POLINEL - DD (dual delay) represents combined system of PK and MS initiators and is used for initiating explosive charge. It is made of initial low energy tube - NES. This tube has DK - 6 (connector) detonator with 0 - 176 ms delay on one, and detonator DK - 8 with 500 ms delay on the other sid

-

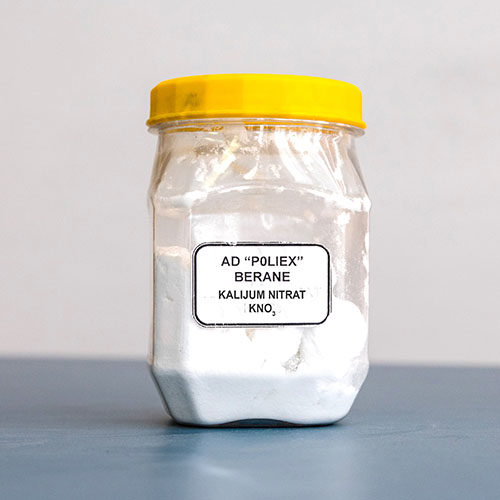

Features:

White crystal powder. Due to its properties it is used in production of composite rocket fuels as well as in pyrotechnics.

-

FEATURES:

Yellow to slightly red crystals. Applied in pyrotechnics but also in production of mineral colors. -

DESCRIPTION

PENTOLITE AMPLIFIERS or “BOOSTERS” are initiation explosive devices designed for initiating less sensitive explosives which do not accept initial impulse from mining caps DK - 8 or detonating cord.APPLICATION

Trotil and penetrate mixture is used for their production. For favorable TNT and PENETRITE ratio and also for their features, molten pentolite boosters are characterized by high water resistance where their mining and technical characteristics are completely maintained and preserved. They are also characterized by high detonation pressure and high detonation speed.INITIATION

The construction of PP - 500 and PP - 300 boosters is adapted to the process of initiation with detonating cord which is wriggled through both spouts and tied by a quadruple node, and the booster is connected to the cartridge of the water resistant explosive by adhesive tape -

APPLIANCE

• White and yellow dough with no additives, • It is formed with hands (no waste), • Maintains reached form (shape), • Density………………………..min. 1,50 g/cm³, • Detonation speed……………..min. 7400 m/s, • Accepts detonating cord initiation impulse (minimum line density 10g/m, weather the detonating cord is wrapped around explosive charge or the explosive charge is formed around the node of the detonating cord) • Transmits detonation from active to passive detonating explosive charge up to 5 cm distance, • Not sensitive to bullet shot, • There is no excudation (liquid component separation), • Handling and transporting is safe, • Protected or not, does not detonate if dropped from 10 m height to solid concrete surface , • Does not contain material that would endanger people’s health, • Has no chemical influence to materials used to build the elements, • Applicable with no restraints regarding hydro-meteorological conditions, • Shaped in dependency of blasting objects and maintains reached shape, • Can be transported in any vehicle, • Maintains physical, chemical and explosive features whilst maintaining quality of shaping and initiating, there is no decomposition or destruction and does not absorb water while reacting: 1. Salty water up to one year and up to 60 m dept, 2. River water up to two months and up to 6 m dept, 3. Atmosphere factors (sun, rain, cold) up to one year, 4. Spring water up to two months, 5. Soil up to 2,5 m dept with frequent underground waters up to 2,5 months. -

DESCRIPTION

Powder explosive BERANIT - 1 (Ø28) is ammonium nitrate - TNT based on ammonium nitrate as oxidant and trinitrotoluene (TNT) as additive with certain addition of organic fuels, substances and means that help protect explosive from moisture and curing.APPLICATION

Since powder explosive is constant at temperature changes it can be successfully applied at both low and high temperatures, with additional moisture protection due to hygroscopic features of the basic component. Depending on detonation speed and brisance, powder explosives BERANIT - 1 is applied in blasting where soft, medium or rocks of high degree of hardness exist in mining (surface mining, pits with no risk of methane or dangerous coal dust appearance), construction works, hydro construction, tunnel construction etc. Combining powder and semi-plastic explosives BERANITS of higher brisance excellent gives excellent results in blasting materials of high degree of hardness. All powder explosives are extremely moisture sensitive even though certain chemical additives, as well as their polyethylene packing, lower the influence of ammonium nitrate hygroscopic features.INITIATION

Powder explosive BERANIT-1 is initiated by a No.8 mining caps, electric detonator, non-electric detonators (system POLINEL) and detonating cord. -

DESCRIPTION

Powder explosives BERANIT - 1, BERANIT - 2 and BERANIT - 3 are ammonium nitrate - TNT based on ammonium nitrate as oxidant and trinitrotoluene (TNT) as additive with certain addition of organic fuels, substances and means that help protect explosive from moisture and curing.APPLICATION

Since powder explosives are constant at temperature changes they are successfully applied at both low and high temperatures, with additional moisture protection due to hygroscopic features of the basic component. Depending on detonation speed and brisance, powder explosives BERANITS, are applied in blasting where soft, medium or rocks of high degree of hardness exist in mining (surface mining, pits with no risk of methane or dangerous coal dust appearance), construction works, hydro construction, tunnel construction etc. Combining powder and semi-plastic explosives BERANITS of higher brisance excellent gives excellent results in blasting materials of high degree of hardness. All powder explosives are extremely moisture sensitive even though certain chemical additives, as well as their polyethylene packing, lower the influence of ammonium nitrate hygroscopic features.INITIATION

Powder explosives BERANIT-1, BERANIT-2 and BERANIT-3 are initiated by a No.8 mining caps, electric detonator, non-electric detonators (system POLINEL) and detonating cord. -

A rocket engine is a type of jet engine that uses only stored rocket propellant mass for forming its high speed propulsive jet. Rocket engines are reaction engines, obtaining thrust in accordance with Newton’s third law. Most rocket engines are internal combustion engines, although non-combusting forms (such as cold gas thrusters) also exist. Vehicles propelled by rocket engines are commonly called rockets. Since they need no external material to form their jet, rocket engines can perform in a vacuum and thus can be used to propel spacecraft and ballistic missiles.

-

Termobarična ručna bomba

features:

• Density 1.6 g/cm3 • Temperature scope from -300C to +600C • Body volume 390g – explosive mass • Sleeve must not break, in the temperature scope, when falls from 12m height on solid ground • Unti-static material (must not be pressed by static electricity) • Chemically stable material on solver