Defensive type hand grenade

-

-

DESCRIPTION

BERANIT is a bran new type of semi-plastic explosive, sensitive to Mining cap number 8. Depending on application conditions it can be delivered in following types 301A and 351.APPLICATION

These explosives do not have evaporation of nitro-oils (as it usually happens with explosives based on nitroglycerine) and also they do not turn into solid mass. Therefore their resistance to external mechanical influences remains consistent for a long period. Do not use in pits with methane or explosive carbon dust! Cartridges are in range from 28 up to 100 mm, paced in water resistant cardboard boxes dim. 350 x 300 x 300 mm, weight up to 20 kg. Cartridges density is in range from 1,30 up to 1,35 g/cm. -

FEATURES:

Bright yellow crystal powder. Applied in photography and in production of anti-hail reagent as active component. -

FEATURES:

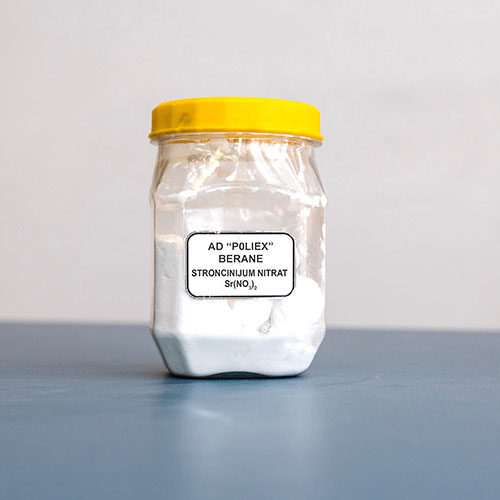

White crystal powder. Mostly applied in pyrotechnics, but also in many other industry fields. -

FEATURES:

• Mortar bomb fuse is not changed during modification into thermobaric. • Mortar bomb case construction is adjusted for HE fragmentation ammunition while saving of case overall dimensions for its change to HE ammunition. • Fragmentation value is not changed for HE fragmentation ammunition. -

FEATURES:

• Mortar bomb fuse is not changed during modification into thermobaric. • Mortar bomb case construction is adjusted for HE fragmentation ammunition while saving of case overall dimensions for its change to HE ammunition. • Fragmentation value is not changed for HE fragmentation ammunition. -

FEATURES:

• HE fragmentation air bomb with fuel-air explosive filling. • Three types of effects: 1.powerful blast effect that exceeds the effect of air bomb analogue in weight 2.fragmentation effect (high-speed fragments) 3.shattering effect • Due to the combined blast, fragmentation and thermal effects created to defeat light armored and unprotected vehicles, fuel and lubricant storages and other targets -

FEATURES:

• HE fragmentation air bomb with fuel-air explosive filling. • Three types of effects: 1.powerful blast effect that exceeds the effect of air bomb analogue in weight 2.fragmentation effect (high-speed fragments) 3.shattering effect • Due to the combined blast, fragmentation and thermal effects created to defeat light armored and unprotected vehicles, fuel and lubricant storages and other targets -

FEATURES:

• HE fragmentation warheads for missile projectiles of multiple rocket launch system “Grad” • Low fire dispersion at increasing distance leads to unacceptable dispersion of projectiles afield, which excludes the effective defeat of the enemy. • Weight of war-head-21 kg • Weight of explosive component - 14 kg • After filling of thermobaric warhead, TNT equivalent will be 35 kg -

FEATURES:

• HE fragmentation warheads for missile projectiles of multiple rocket launch system “Grad” • Low fire dispersion at increasing distance leads to unacceptable dispersion of projectiles afield, which excludes the effective defeat of the enemy. • Weight of war-head-19,18 kg • Weight of explosive component - 6,4 kg • After filling of thermobaric warhead, TNT equivalent will be 16 kg -

DESCRIPTION

Water resistant plastic explosives BERANIT - 30 P and BERANIT - 37 besides AN as oxidant and TNT as combustible component also contain water and highly molecular plasticizers which help them maintain high water resistance, high density, high and stabile detonation speed and above all high brisance as well as extremely safety feature.APPLICATION

Considering all above mentioned features these explosives are recommended whilst mining rocks of highest degree of hardness on surface drill holes (because of their negative oxygen ratio) especially where possible presence of water is expected. Since they are extremely resistant to hydrostatic pressure and since they have extremely constant detonation speed for given diameters, we recommend them even for seismic tests.INITIATION

For not being sensitive to initial impulse of DK - 8 and detonating cord for their initiation detonation booster has to be used. In order to obtain full detonation speed we suggest molten (plastic) boosters whose diameter should be approximate to cartridge diameter. Come to booster and detonating cord, initiation is to be done from the top of the drill hole, and in case blasting is done with booster and Nonel (Polinel) detonator initiation is to be done from the bottom of the drill hole.